Why Aluminium Die Casting is More Effective

The expert the people who have been working in the industry relating to metal know about the aluminium die casting. In actuality, the commoners are not having any sort of thought regarding this phrasing. This is a cycle that is by and large utilized in the business connecting with aluminium and it has diverse advantages over the various kinds of metal. You will come to know why this metal has a place with the best option.

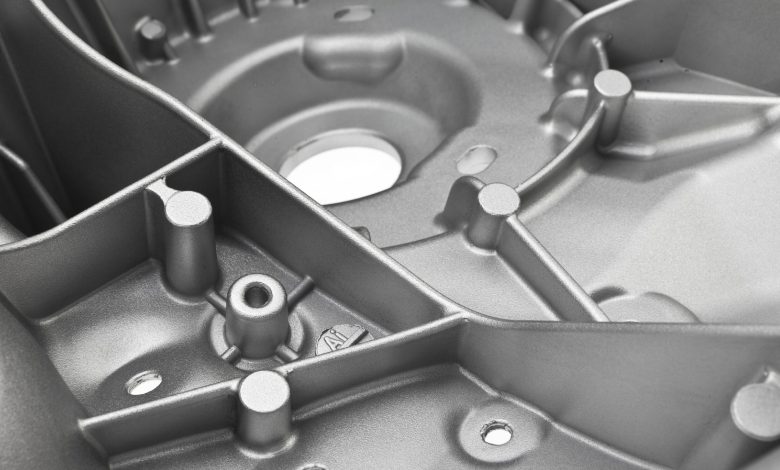

The meanings of aluminium die-casting – It is vital to have a ton of familiarity with die casting and its job all along as well as what is it. It is a cycle where the melted metal is constrained at high pressure into the form dies by die casting mould manufacturers. It is by a long shot the most economical strategy to deliver aluminium pass on projecting parts to date.

The cycle has been partitioned into two sections, for example, gravity die casting and pressure die casting. The gravity dies casting is an interaction where medium volume creation is achieved, while, the pressure die casting cycle is finished with a high volume of creation. There are two arrangements of machines associated with the cycle. One is the cold chamber and another one is the hot chamber. The cold chamber is utilized with the end goal of a high softening point for aluminium and different sorts of metals. The hot chamber is utilized for multipurpose exercises.

Why the aluminium is the most ideal decision – Though other metals, for example, copper, zinc and magnesium can be utilized, aluminium is the best one because of its gentility and cost sufficiency. The aluminium has adaptable mechanical properties. Aluminium gives a lot of advantages and benefits in contrast with different metals. A few fundamental advantages have been depicted beneath.

Being aluminium is a delicate metal, it can deliver an expanded scope of shapes and sizes. It can make the surface either adequately smooth or a finished surface that relies on you what you want.

The advantage with this metal is hostile to destructive and doesn’t get annihilated by sun, downpours and cold and so forth. Since the aluminium die casting interaction requires no sort of finish, it paces the work cycle. However it is hostile to destructive, a few geological regions, for example, the coast can hurt this delicate metal. That is the reason; it is painted with marine varieties which can save the time span of usability.

The aluminium is equipped to hold its solidarity at a high temperature which permits it to have diverse shapes and plans. Here the work should be possible with the most slender divider. This isn’t conceivable if there should be an occurrence of different metals. Indeed, plastic can’t be pretty much as adaptable as aluminium in the die casting mould.

As we probably are aware die casting is acquiring renown step by step in numerous enterprises for their metal parts for making machine parts, toys, machines and numerous different kinds of use too. Aluminium is perhaps all that metal that can be utilized in diverse ways. This metal is viewed as a shelter to the individual.

Read More: Aluminium Shop Fronts the Best Choice for Securing Your Shop