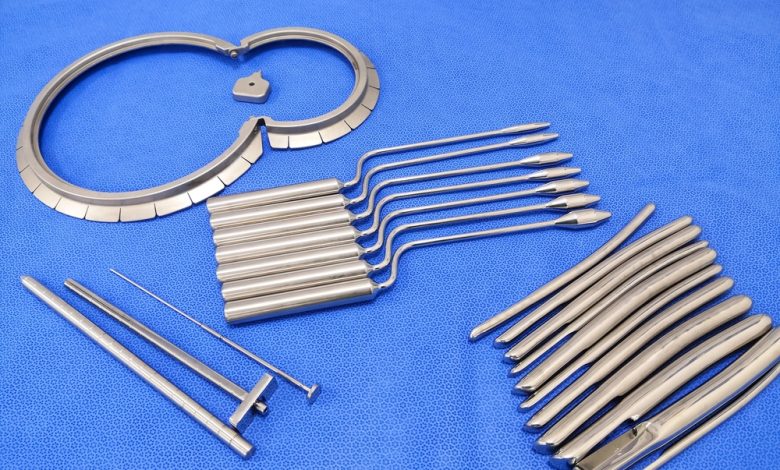

Retractors: Their Uses, Maintenance, and Sterilization

An orthopedic retractor, which is usually attached to a flexible arm, positions the patient so that a securing mechanism may operate to allow access to the surgical site to insert tubes, perform endoscopy, and use other surgical tools well.

Tips and tricks that will be useful

Caution

It is important to remove all of the covers and sheaths carefully. It is crucial to thoroughly clean, lubricate, decontaminate, disinfect, and examine the retractors and its accompanying tools before allowing them to undergo surgery. It is advisable to use unsterile or reusable instruments.

Because it is such a precise instrument, the retractor presents a risk of injury. Therefore, it is important to handle it carefully so that it performs correctly. Handling it incorrectly can make the product go haywire, resulting in serious malfunctions.

It should undergo testing before use

Before using a surgical retractors, it is necessary to thoroughly inspect and prepare its components. Before using, please be sure you double-check everything. Putting the finishing touches on the process. After positioning the retractor in the right position, secure the locking mechanism by pressing the button. If it is safe and ready to use, check to make sure.

Application

Only the most qualified and experienced neurosurgeons should be able to perform brain and nervous system surgeries. Before having any kind of surgery on your brain, make sure you know about the treatment itself, as well as the procedures, problems, and possible risks.

It is important to study the product’s features regarding safety as well as the method of the surgical procedure before using it. There is a sterile retractor with a shaft that goes into the body. To use the retractor, one must have proper training in how to do so. You will follow a standard procedure on how to use it in the operating room.

Exposure to contamination

Sanitation and Decontamination

Please bring your instrument and adapter(s) to a decontamination area. The instrument, adapter (s), and accessories should be cleaned, disinfected, and sterilised according to the instructions in the IFUs. It is important that you are aware of the high risk of infection. Before using an instrument, it is important to disinfect all of the instrument’s components, including the adapters and any other extra accessories. If the decontamination process isn’t enough, inaccurate, or superficial, patients and/or people who use it could get sick.

Maintain cleanliness

If you wish to clean the instrument externally, you can use a soft sponge and brush. It is important to remove the retractor adapters before attempting to disinfect the instrument. When doing manual or automated cleaning, make sure to follow the General Instruments instructions for use. Because of the potential for harm, ultrasonic baths are probably not the best choice when it comes to cleaning. The adapter (s) should remain out of the retractor until you are ready to use it again. Also, make sure that the threads have been thoroughly dried before you start using them.

Sterilization

Sterilization of autoclaves by steam is the only approved method of disinfection. During the autoclave’s standard cycle, it sterilizes for fifteen minutes with steam at 270°F. Different steam cycles at different temperatures are available as well. All deviations from the recommended time and temperature are up to the user.

Please check with the manufacturer of your steam autoclave about proper sterilisation temperatures and timeframes. Handles, insulation, and other nonmetallic components may suffer damage if temperatures in the autoclave rise above 280°F. Sterilisation requires a properly sealed instrument container. Make sure you follow the hospital’s hygienic cleaning protocols when sterilising. Wrangler Instruments’ instruments are sterile and reusable. It is important to separate the retractor from other equipment when cleaning it.

Care and maintenance

Don’t lubricate anything other than the moving pieces and connecting pieces (lock mechanism).

Examine and repair

An authorised service agency should be in charge of all repairs to the precision retractor to make sure that they all follow the manufacturer’s instructions. This way, the precision retractor will be safe.

Assurance

For the convenience of our customers, Wrangler Surgical Instruments offers a warranty on all purchases made from us in order to ensure you are getting the best product for your money. Every product we offer meets the highest quality standards.

How to Properly Use, Clean, and Maintain Orthopedic Retractors

Orthopedic retractors are a crucial tool in accessing surgical sites during procedures. They are attached to a flexible arm that can be adjusted to the desired position. However, to ensure patient safety, it is important to follow proper protocols when using, cleaning, and maintaining these instruments.

Before use, it is essential to inspect and prepare all components of the retractor. The locking mechanism must be securely fastened, and the retractor should be positioned correctly. Only qualified and experienced neurosurgeons should perform brain and nervous system surgeries and have proper training on the specific instrument they will use.

To prevent contamination, all retractors and accompanying tools should be thoroughly cleaned, decontaminated, and disinfected before each use. It is important to follow the manufacturer’s instructions for use (IFUs) and to disinfect all components, including adapters and accessories. Sanitation and decontamination must be done in a designated area to avoid exposure to other patients or staff members.

To maintain cleanliness, use a soft sponge and brush to clean the instrument externally, and remove the adapters before disinfecting the instrument. Ultrasonic baths should be avoided as they can potentially cause harm. After cleaning, the instrument should be sterilized in an autoclave using steam at the recommended temperature and time.

Proper care and maintenance of the retractor are also crucial to ensure its longevity and safety. Only lubricate the moving and connecting pieces of the instrument and have any necessary repairs done by an authorized service agency.

At Wrangler Surgical Instruments, we offer a warranty on all our products and ensure that each product meets the highest quality standards. By following proper protocols for the use, cleaning, and maintenance of orthopedic retractors, we can help ensure the safety and well-being of patients.

Read More: Solar Panel Installation And Maintenance Step-By-Step Process